|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance WEB™ |

|

Our Web version of EZ

Maintenance™, EZM Web™

is accessible anywhere in the

world there is an internet

connection.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ for Web |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

Previous

Section:

Entering

and Viewing Equipment Entering

and Viewing Equipment |

Next

Section:

Maintenance

Due Reports |

Click here to see a video on Viewing Maintenance Due.

|

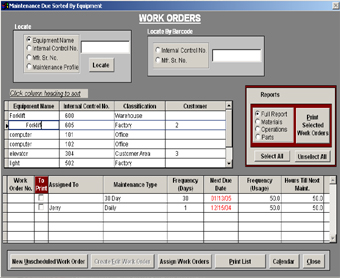

Maintenance

Due

Being able to quickly and easily determine which

preventive maintenance is due and overdue is one of the most important

issues in tracking and controlling preventive maintenance. A complete

schedule of preventive maintenance, for any time period, can be pulled

using EZ Maintenance equipment maintenance software. A user can easily view

Maintenance

Due schedules By Equipment or By Date.

"By Equipment"

displays the following screen: 'Maintenance Due Sorted

By Equipment'.

|

Maintenance

Due Sorted By Equipment lists the equipment to

be maintained, and the preventive maintenance due for each equipment

unit. For any Equipment Name selected, you will see a

list of all its pending preventive maintenance. Projected maintenance

due and open Work Orders are viewed here. Maintenance

Due Sorted By Equipment lists the equipment to

be maintained, and the preventive maintenance due for each equipment

unit. For any Equipment Name selected, you will see a

list of all its pending preventive maintenance. Projected maintenance

due and open Work Orders are viewed here.

Locate functions

assist in quickly finding equipment from the list on the

table in the middle of the screen.

Type to Locate Select

the equipment detail you wish to enter for sorting purposes,

then type in that detail, and click Locate. The particular

equipment piece you've chosen will be highlighted in the

lower screen.

Scan a Barcode to Locate

Select the Barcode scan format, then scan the equipment

Barcode, and click Locate. The particular equipment piece

you've scanned will be highlighted in the lower screen.

New Unscheduled Work Order

Emergency, unplanned preventive maintenance requires clicking on

New Unscheduled Work Order. Use the drop down menus (pre-entered

SETUP data) to select a piece of equipment, fill in its

details, and the required preventive maintenance to be covered in

the New Unscheduled Work Order.

Create/Edit Work Order

Create or edit a Work Order for a preventive maintenance event by

first selecting the event from the lower left grid, then

clicking the Create/Edit Work Order button. A preventive maintenance

Work Order is then created and a Work Order Number is

assigned automatically.

Assign Work Orders

Clicking the Assign Work Orders button will take you to a screen that will

allow

you to assign each work order you create to a specific person or employee.

This

is to be done by Managers and Supervisors only.

Calendar creates

a visual agenda of preventive maintenance events, which are past

due, due today, this week, this month, etc., by selecting

the specific date range you wish to view.

Next Due Date column,

on the far left, is important as it lists the oldest,

uncompleted preventive maintenance events or opened, but not completed

Work Orders. If the manager determines a preventive maintenance event

should have a Work Order produced, he/she will simply

select the event and click Create/Edit Work Order.

|

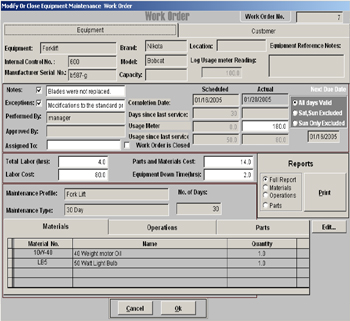

Notes

& Exceptions fields allow the supervisor to

enter notes as to what was done, or if there were any

variances. Both fields accept a great deal of typed information

for precise note sharing. Notes

& Exceptions fields allow the supervisor to

enter notes as to what was done, or if there were any

variances. Both fields accept a great deal of typed information

for precise note sharing.

Performed By establishes

accountability for the equipment's preventive maintenance history.

Approved By Only

a supervisor with the proper password may sign off or

close a Work Order.

Assigned To allows a manager to assign

the

work order to a specific employee.

Labor Hours, Materials Cost

& Equipment Down Time are entered by the supervisor

closing out the Work Order.

Materials, Operations, Parts

are automatically entered based on set up of the Maintenance

Profile.

|

| Click

here to view an actual Work Order |

Previous

Section:

Entering

and Viewing Equipment Entering

and Viewing Equipment |

Next

Section:

Maintenance

Due Reports |

|

|

|

| 1. |

How do we track what work was actually done and when? |

| |

Completed preventive maintenance and service activity can either be electronically signed off as completed within EZ Maintenance preventive maintenance software by the person performing the work, or a work order with a signature line can be printed, which can be signed by the person performing the work, and then filed as a hard copy. Such work orders contain a list of all procedures to be performed and the materials to be used, so once signed a verified record exists that not only the preventive maintenance or service was performed, but the exact procedures followed and the parts and materials used, and all costs. |

| 2. |

What happens if we miss a scheduled maintenance or service? |

| |

EZ Maintenance fleet maintenance software allows a supervisor to note the reason, and to reschedule the work (this must be done by a supervisor so work cannot be missed or rescheduled without management control). When the work is rescheduled and completed, EZ Maintenance fleet maintenance software automatically adjusts the calendar by rescheduling the balance of the maintenance . In other words, if a weekly preventive maintenance day is missed by four days, and the work is then done, EZ Maintenance fleet maintenance software reschedules the rest of the maintenance weekly from the day the work was actually done. |

| 3. |

Can we enter both detailed instructions on how the scheduled maintenance or service is to be performed and the parts and materials required? |

| |

Yes, and a work order can be printed listing all procedure and parts/materials. |

|

|

|

|

|

|