|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance WEB™ |

|

Our Web version of EZ

Maintenance™, EZM Web™

is accessible anywhere in the

world there is an internet

connection.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ for Web |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

|

|

Watch a Video about Tracking Inventory in EZ Maintenance

Tracking Your Inventory Using EZ Maintenance

EZ Maintenance has a complete inventory tracking system that tracks the

quantity on hand for all of your inventory items along with many other

features.

EZ Maintenance also automatically deducts items from inventory that

are used in work orders. EZ Maintenance tracks the date on

which the quantity of an item was used in the work order and the

quantity/amount that was used. When inventory is received, the quantity that

is received and the date on which it was received is recorded. In other

words, for each type of inventory item you track in EZ Maintenance, the

program keeps a complete record of when items are used and deducted from

inventory, when they are received, and also when more than necessary was

checked out and needs to be returned to the inventory.

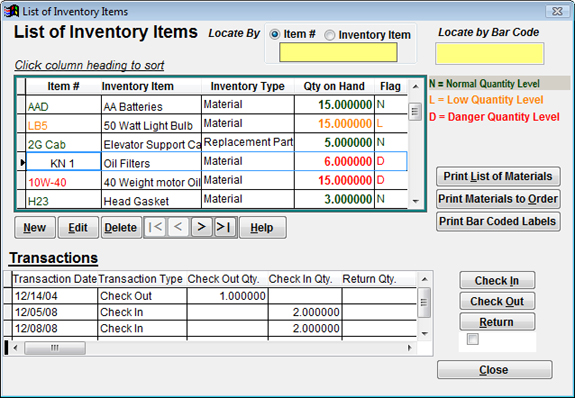

At this window you can track all of your inventory and see the levels of

each item you are tracking:

Each inventory item you are tracking is shown in this window. The name of

each inventory item is shown along with its unique tracking number, whether

it is a material that is used in maintenance or an entire replacment part,

and the quantity of it you have in stock. You can also see, at a glance,

whether the inventory item is at a normal level, a low level, or at a

critically low level based on the color that the quantity is displayed in

(green means normal, yellow means low, and red means critically low and that

some more should be reordered.

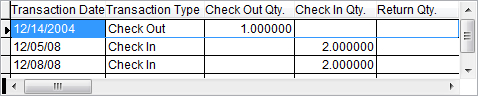

At this window you'll also see the list of transactions for the selected

inventory item:

For each transaction, the date of the transaction is shown along with its

type (e.g. Check Out, Check In, or Return), and the quantity. A check out

transaction is when a quantity is removed from the inventory for use; for

example, EZ Maintenance, automatically creates check out transactions and

deducts from the inventory quantity when an item is used in a work order. A

check in transaction is when a quantity is received into inventory; EZ

Maintenance also automatically creates a check in transaction and adds to

the inventory quantity when the Inventory Receiving feature of EZ

Maintenance is used. A return transaction is made when a quantity of an

inventory item was checked out which was more than needed, and the remaining

quantity needs to be returned to inventory.

You can create Check In, Check Out, and Return transactions yourself using

the three buttons to the right:

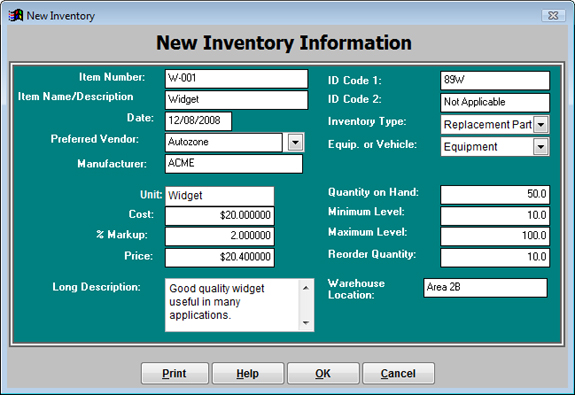

Entering New Inventory Items into EZ Maintenance

To enter new inventory items into EZ Maintenance to track them, just click

on the New button below the list of inventory items. This

takes you to a form where you fill out the information for the new inventory

item:

The following information can be entered for the inventory item:

Basic information about the inventory item: it's

unique item number, its name, the date

on which the item is entered into EZ Maintenance, the vendor

from whom you prefer to buy this item, and the manufacturer.

You can also specify the unit in which this item is measured (e.g. "Quart"

for motor oil.)

Cost and Pricing: you can also enter the cost

per unit for this inventory item and the markup you

charge when selling this item to your customers. The cost plus

the markup is automatically calculated and displayed in the

Price field.

A detailed description of the inventory item: enter

a detailed description of the item into the Long

Description field.

Alternative identifying ID numbers: you can also

enter alternative identifying numbers into the ID Code 1 and ID Code 2

fields. These can be used, for example, to enter item codes that your

suppliers might use.

Whether the item is a material or a replacement part and whether

it is used in equipment maintenance, vehicle maintenance, or

both.

Quantity Information: you can enter the quantity

currently on hand, the minimum level allowed

in inventory, the maximum level allowed in inventory, and

the quantity at which you re-order this inventory

item.

Where this item is stored: enter where the item is

stored in the Warehouse Location field.

Clicking on the OK button after all of the information has

been entered for the inventory item puts the item into EZ Maintenance for

tracking.

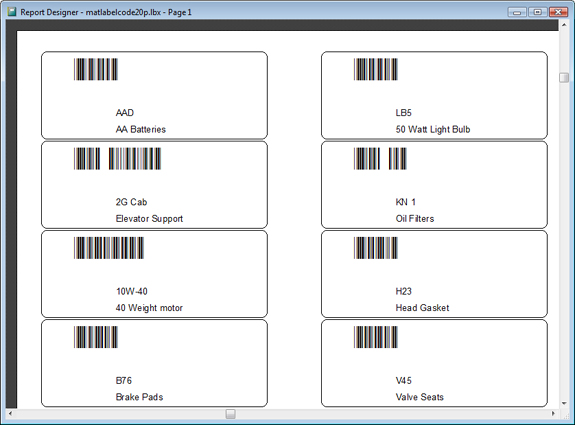

Using Barcoding with Inventory Items

EZ Maintenance also has a feature that lets you print barcode labels for

your inventory items and then scan them to locate them in the software. The

following is a sample printout containing barcodes produced by EZ

Maintenance:

|

|

|

|

|

|

|

|