"For saltwater application the aluminum bronze offers increased

corrosion resistance over CA-6NM stainless steel.

corrosion resistance over CA-6NM stainless steel.

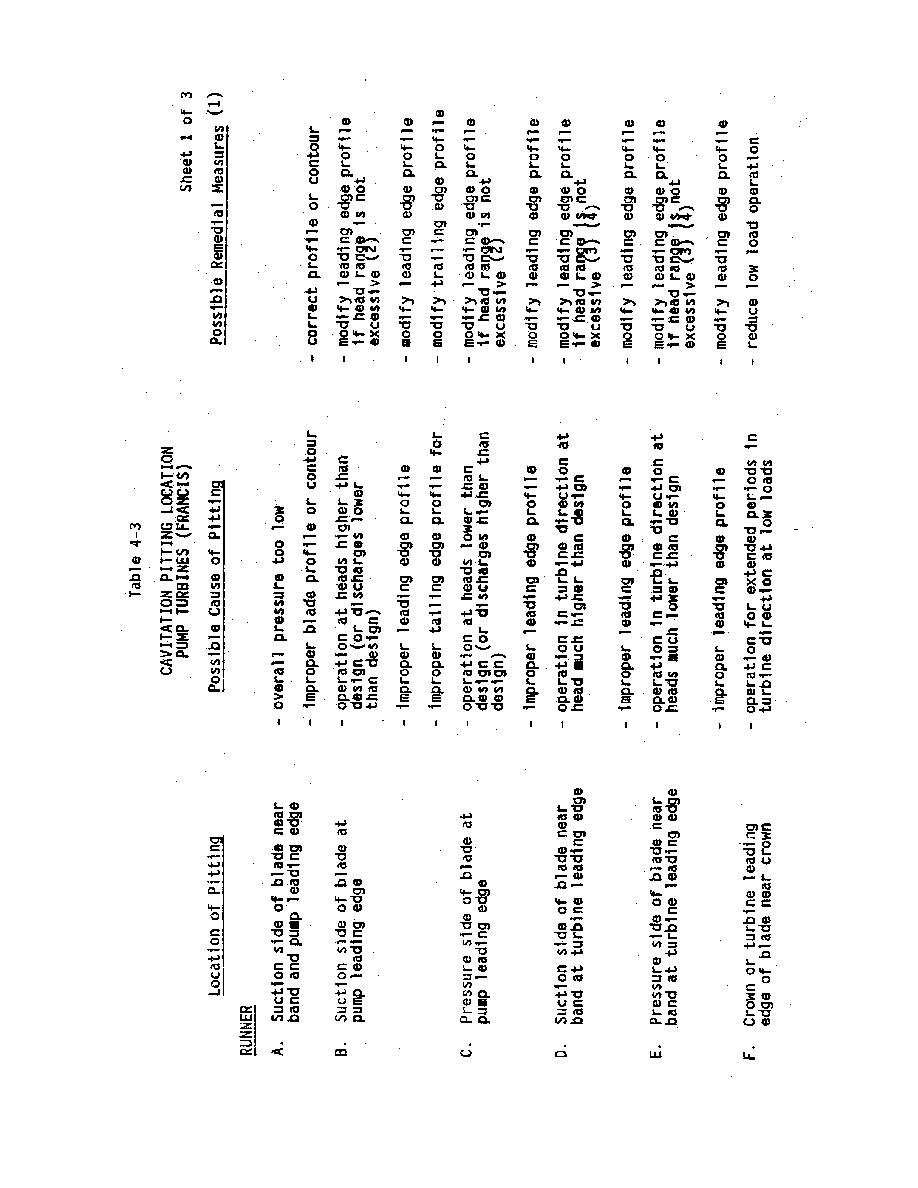

3. CAVITATION

Examination of the runner of a hydraulic turbine or the impeller of a pump

often discloses pitted areas in various stages of development. Pitted areas

may also be found on turbine or pump water passage surfaces where water

velocities are high. This damage is generally termed cavitation erosion or

impingement erosion. Because of various physical conditions present in the

waterflow system, a cycle of cavitation is induced as follows:

often discloses pitted areas in various stages of development. Pitted areas

may also be found on turbine or pump water passage surfaces where water

velocities are high. This damage is generally termed cavitation erosion or

impingement erosion. Because of various physical conditions present in the

waterflow system, a cycle of cavitation is induced as follows:

a. Extreme low pressure areas are produced by flow irregularities.

b. Pockets or "cavities" of vapor form.

c. Pressure and flow conditions change abruptly.

d. The pockets or "cavities" collapse causing high shock pressures.

e. Where the collapse occurs adjacent to a metal surface, the resultant

impact tears out bits of the metal.

impact tears out bits of the metal.

The cycle occurs at a very high frequency. As the metal surface deteriorates,

the damage rate accelerates rapidly. Without timely repair, the cavitation

process can result in the total destruction of the surface under attack.

the damage rate accelerates rapidly. Without timely repair, the cavitation

process can result in the total destruction of the surface under attack.

4. CAVITATION REPAIR

The following sections 4.1 through 4.8 have been reprinted by permission

from EPRI AP-4719. (2)

from EPRI AP-4719. (2)

4.1 "APPROACH

"The repair of cavitation pitting damage on turbines is an essential part of a

hydro plant maintenance program. If left unrepaired, or if improperly repaired,

the extent of damage will increase, usually at an accelerating rate, eventually

leading to an extended and costly outage of the unit.

hydro plant maintenance program. If left unrepaired, or if improperly repaired,

the extent of damage will increase, usually at an accelerating rate, eventually

leading to an extended and costly outage of the unit.

4