grinders are required for every three welders; personnel should be allocated in that

basis.

basis.

"On large units the runner may be divided into isolated sections by hanging canvas

tarpaulins between the blades. This will allow simultaneous repair on several blades

without interference between welders and grinders.

tarpaulins between the blades. This will allow simultaneous repair on several blades

without interference between welders and grinders.

"Multiple shifts may be used to separate the welding and grinding work and also to

reduce the overall unit down time."

reduce the overall unit down time."

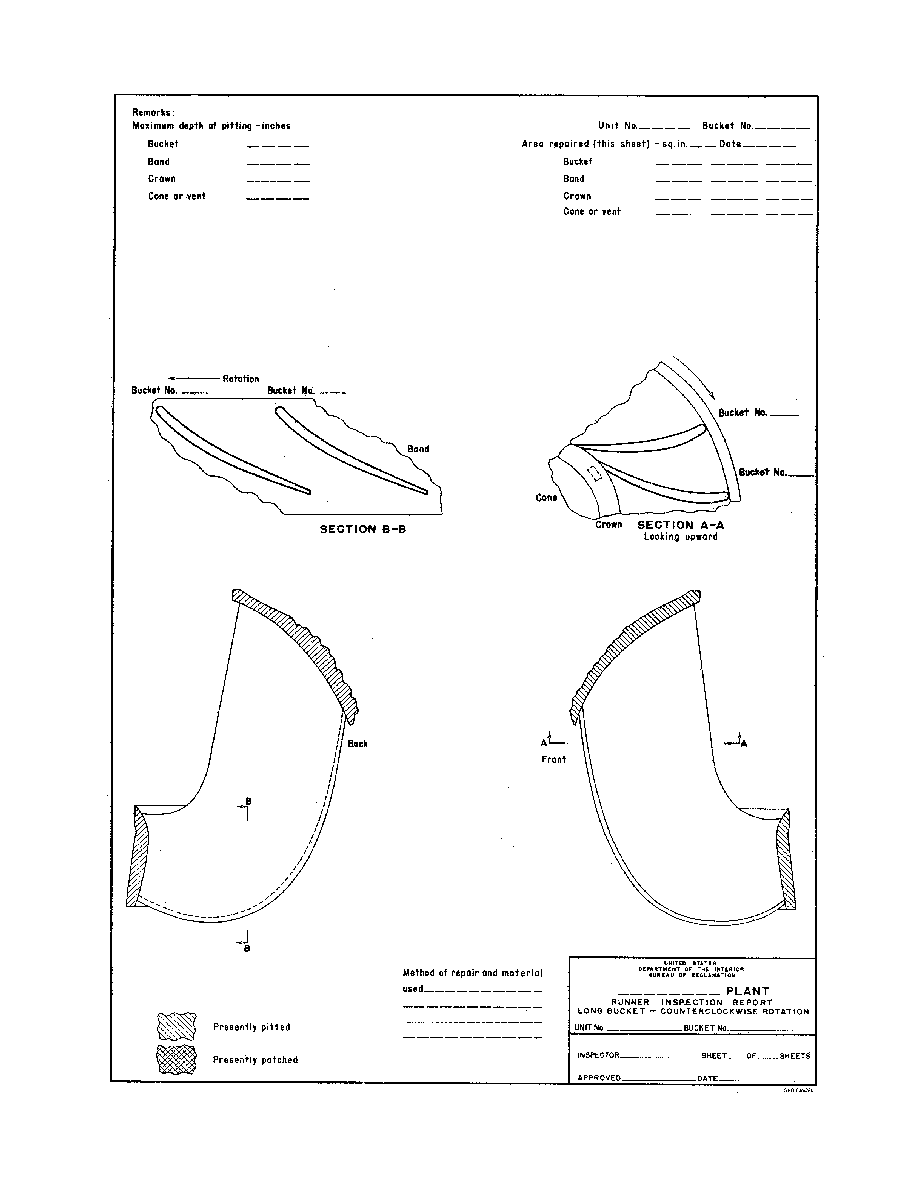

4.9 DOCUMENTATION FORMS

Standard Reclamation forms are available for recording runner damage and repairs.

These forms include P.O. and M. 160 for long buckets and clockwise rotation, P.O.

and M. 161 for long buckets and counterclockwise rotation, and P.O. and M. 162 for

short buckets.

These forms include P.O. and M. 160 for long buckets and clockwise rotation, P.O.

and M. 161 for long buckets and counterclockwise rotation, and P.O. and M. 162 for

short buckets.

5. CRACK REPAIR

Cracks may appear which are caused by localized residual stress or solid objects

striking the blades of the unit. Records should be kept on the locations and lengths of

these cracks. A crack can relieve the residual stress and no further cracking will

develop. Holes drilled at the ends of the crack, a procedure known as stop drilling, will

often arrest the growth of the crack.

striking the blades of the unit. Records should be kept on the locations and lengths of

these cracks. A crack can relieve the residual stress and no further cracking will

develop. Holes drilled at the ends of the crack, a procedure known as stop drilling, will

often arrest the growth of the crack.

As a general rule, welding of runner cracks should not be attempted unless the

structural integrity of the runner is questionable. Welding can lock stresses in the

runner that will eventually cause more severe cracking. The Hydroelectric Research

& Technical Services Group, D-8450, should be consulted before crack repair welding

is attempted.

structural integrity of the runner is questionable. Welding can lock stresses in the

runner that will eventually cause more severe cracking. The Hydroelectric Research

& Technical Services Group, D-8450, should be consulted before crack repair welding

is attempted.

6. WELDING ELECTRODES

The American Welding Society classification of mild and low alloy steel electrodes

and filler rods uses a four- or five-digit number with a prefix of either "E" or "R." The

"E" stands for electrode and signifies arc welding. The "R" stands for rod and signifies

gas welding. The first two or three digits indicate the minimum tensile strength. For

example, an E6018 electrode has a minimum tensile strength of 60,000 lb/in2 (4.14

x 108 N/m2), and an El1018 electrode has a minimum tensile strength of 110,000

lb/in2 (7.58 x 108 N/m2). The next to last digit indicates which welding position the

electrode can be used for. A "1" in this position indicates an

and filler rods uses a four- or five-digit number with a prefix of either "E" or "R." The

"E" stands for electrode and signifies arc welding. The "R" stands for rod and signifies

gas welding. The first two or three digits indicate the minimum tensile strength. For

example, an E6018 electrode has a minimum tensile strength of 60,000 lb/in2 (4.14

x 108 N/m2), and an El1018 electrode has a minimum tensile strength of 110,000

lb/in2 (7.58 x 108 N/m2). The next to last digit indicates which welding position the

electrode can be used for. A "1" in this position indicates an

electrode that can be

28