"Preheat temperatures may be 150 F (83 C) less than given above for carbon steel

weld materials, however, should not be less than 60 F (16.C).

weld materials, however, should not be less than 60 F (16.C).

"Austenitic Stainless Steel Weld Material on Austenitic Stainless Steel. A nominal

60 F (16 C) preheat is necessary.

60 F (16 C) preheat is necessary.

"Austenitic Stainless Steel Weld Material on M@rtensitic Stainless Steel (CA6NM).

The minimum preheat should be as follows:

The minimum preheat should be as follows:

4 in. (102 mm) material thickness ............................150 F (66 C)

4 in. (102 mm) material thickness ............................250 F (121 C)

In restricted areas, preheat should be increased by 100 F (56 C).

Stellite 21 Weld Material. A nominal 60 F (16 C) preheat is necessary.

Preheating may be done using:

Oxy-acetylene torches (for small areas)

Propane or butane

Electric strip heaters with insulating blanket

Quartz lamps

Propane or butane

Electric strip heaters with insulating blanket

Quartz lamps

Where there are large areas to be preheated, insulating blankets are needed to

protect personnel during the subsequent welding. Preheat temperature should be

monitored using a contact pyrometer or temperature-indicating crayons.

protect personnel during the subsequent welding. Preheat temperature should be

monitored using a contact pyrometer or temperature-indicating crayons.

During preheating, care should be taken that the center of a blade is not heated in a

small concentrated area. To allow for expansion of the material, heat should be

applied starting from the outer edge of the blade.

small concentrated area. To allow for expansion of the material, heat should be

applied starting from the outer edge of the blade.

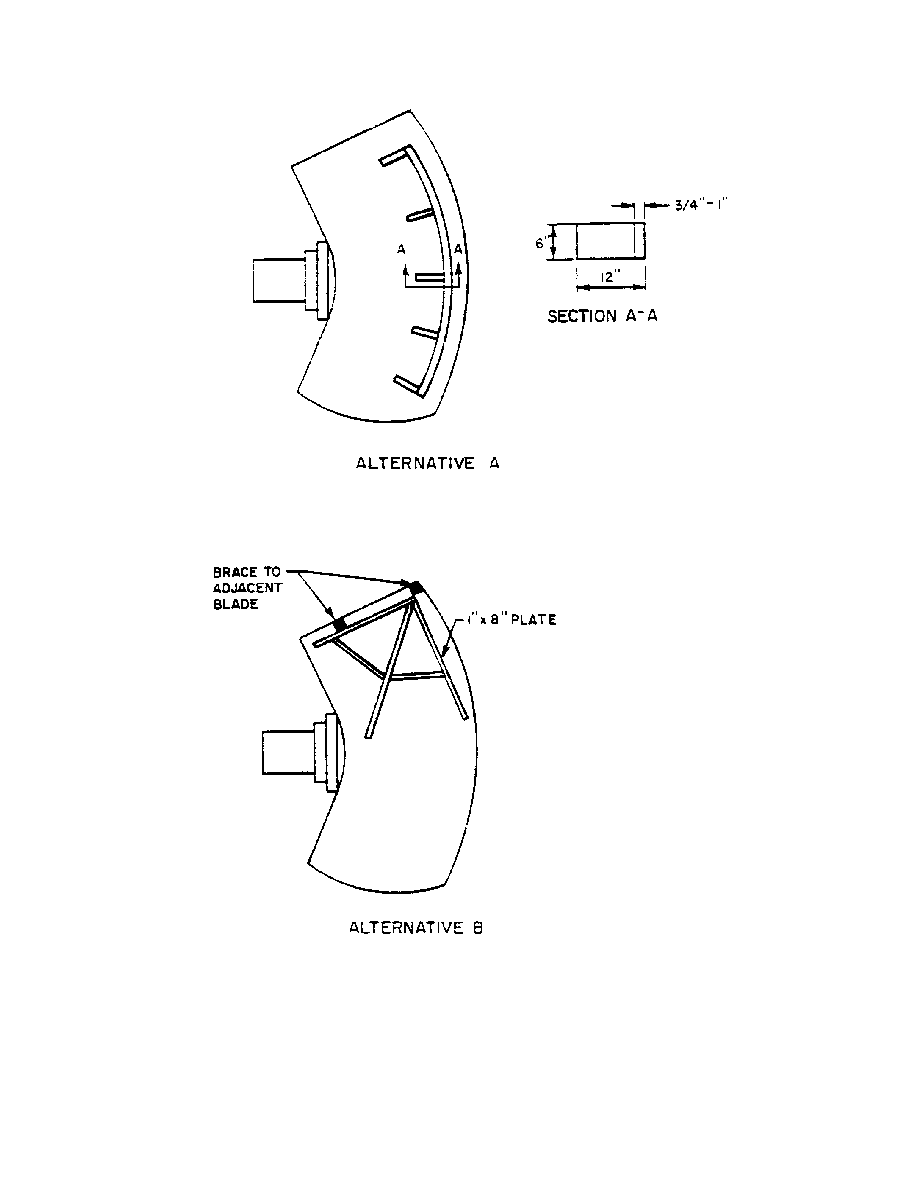

Weld Application. Weld application should be aimed at achieving good quality weld

with minimum residual stressing and also at keeping distortion to an absolute

minimum. This can be accomplished by:

with minimum residual stressing and also at keeping distortion to an absolute

minimum. This can be accomplished by:

Apply no more than 1/8 inch (3 mm) weld material per pass.

Limit heat input to the runner. The maximum interpass temperature should

be within 200 F (111 C) of the minimum preheat temperature. Temperature

should be monitored with a contact pyrometer or temperature-indicating

crayons. In addition, the area about 4 inches (102 mm) from the weld should

not become to warm to touch.

be within 200 F (111 C) of the minimum preheat temperature. Temperature

should be monitored with a contact pyrometer or temperature-indicating

crayons. In addition, the area about 4 inches (102 mm) from the weld should

not become to warm to touch.

19