"Research is being done by the CEA on the use of the pulsed arc method of field

repair with the gas metal arc welding process. This technique can provide more

stable overhead and vertical welding when compared to the older spray transfer

process.

repair with the gas metal arc welding process. This technique can provide more

stable overhead and vertical welding when compared to the older spray transfer

process.

"When selecting a weld process, the preference and experience of the welder

should be considered. With the GMAW process in particular, lack of experience

may offset any advantages of this process.

should be considered. With the GMAW process in particular, lack of experience

may offset any advantages of this process.

"Repair Procedures. The procedures developed for cavitation repairs are site

specific because of the many factors involved. It is recommended that

procedures be established for each repair program to maintain a consistent

approach, to monitor the results and to avoid excessive costs in any one area

of the program.

specific because of the many factors involved. It is recommended that

procedures be established for each repair program to maintain a consistent

approach, to monitor the results and to avoid excessive costs in any one area

of the program.

"These procedures should be modified to incorporate any changes which could

benefit subsequent repairs. The items discussed below illustrate some of the

important points which should be covered by the procedures.

benefit subsequent repairs. The items discussed below illustrate some of the

important points which should be covered by the procedures.

"Initial Dimensional Checks. Prior to the start of cavitation repairs to a turbine

runner, dimensional checks should be made. These will serve as a basis for

determining whether or not weld distortion has occurred and also to establish

whether or not any measures are necessary to correct distortion which may have

occurred during a previous repair or during initial runner manufacture.

runner, dimensional checks should be made. These will serve as a basis for

determining whether or not weld distortion has occurred and also to establish

whether or not any measures are necessary to correct distortion which may have

occurred during a previous repair or during initial runner manufacture.

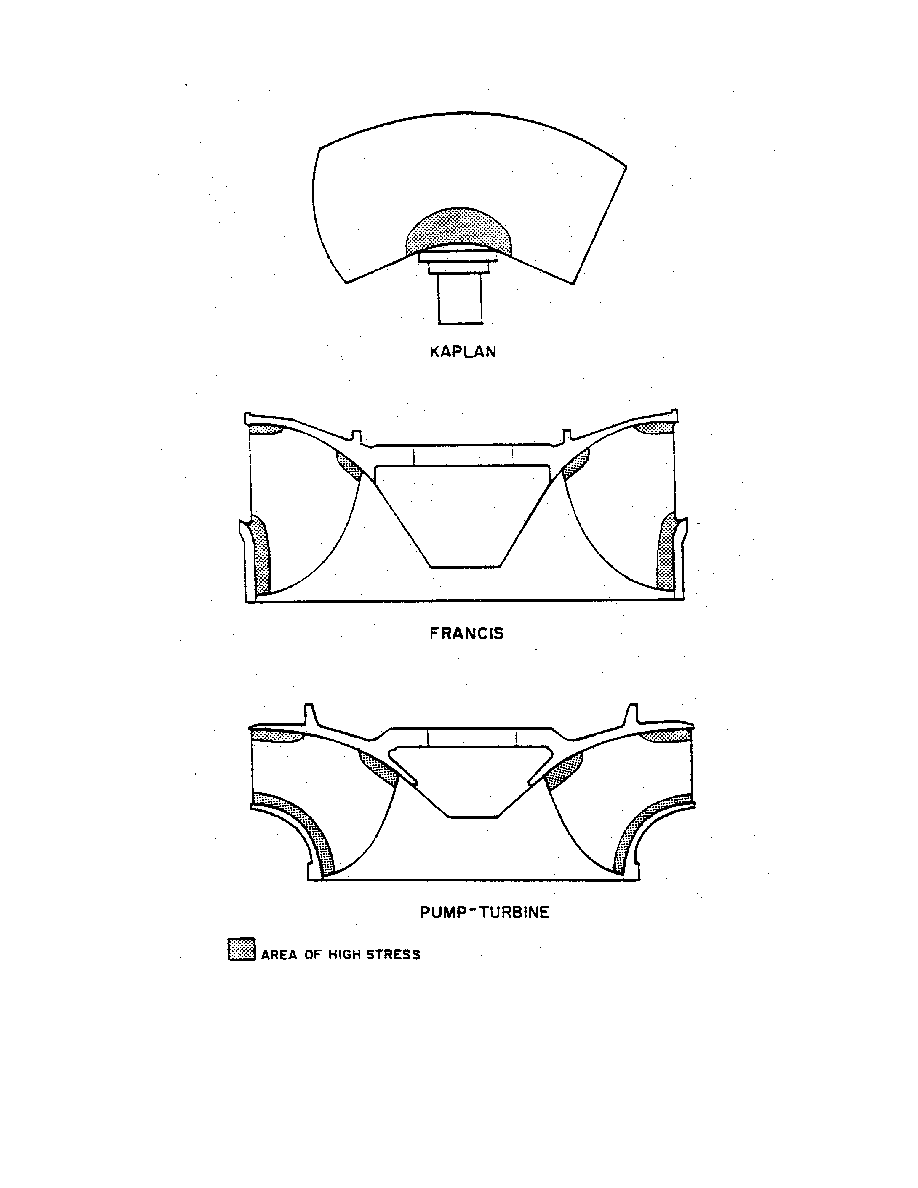

Propeller and Kaplan Runners. The pitch angle of each blade should be

recorded, using the bottom ring elevation of the top of the draft tube liner

as a datum (

recorded, using the bottom ring elevation of the top of the draft tube liner

as a datum (

Vent checks of the discharge area of the runner should also be made.

This check is made by measuring the closest distance between adjacent

blades, at the discharge edge.

This check is made by measuring the closest distance between adjacent

blades, at the discharge edge.

Francis Runners. A vent check should be made as mentioned above for

propeller and Kaplan turbines (

propeller and Kaplan turbines (

). From the vent

measurements, the average opening between each pair of blades, the

overall average opening, and a variance from average of each opening

can be calculated. Corrective action should be taken if there is large

variation in vent openings, particularly if oversize vent openings are

grouped together on one side.

overall average opening, and a variance from average of each opening

can be calculated. Corrective action should be taken if there is large

variation in vent openings, particularly if oversize vent openings are

grouped together on one side.

16