16

Upper Wear Ring

Thrust Runner

1st Band

2nd Band

Centerline of

Coupling

3rd Band

4th Band

Lower Wear Ring

A

E

B

C

D

G

F

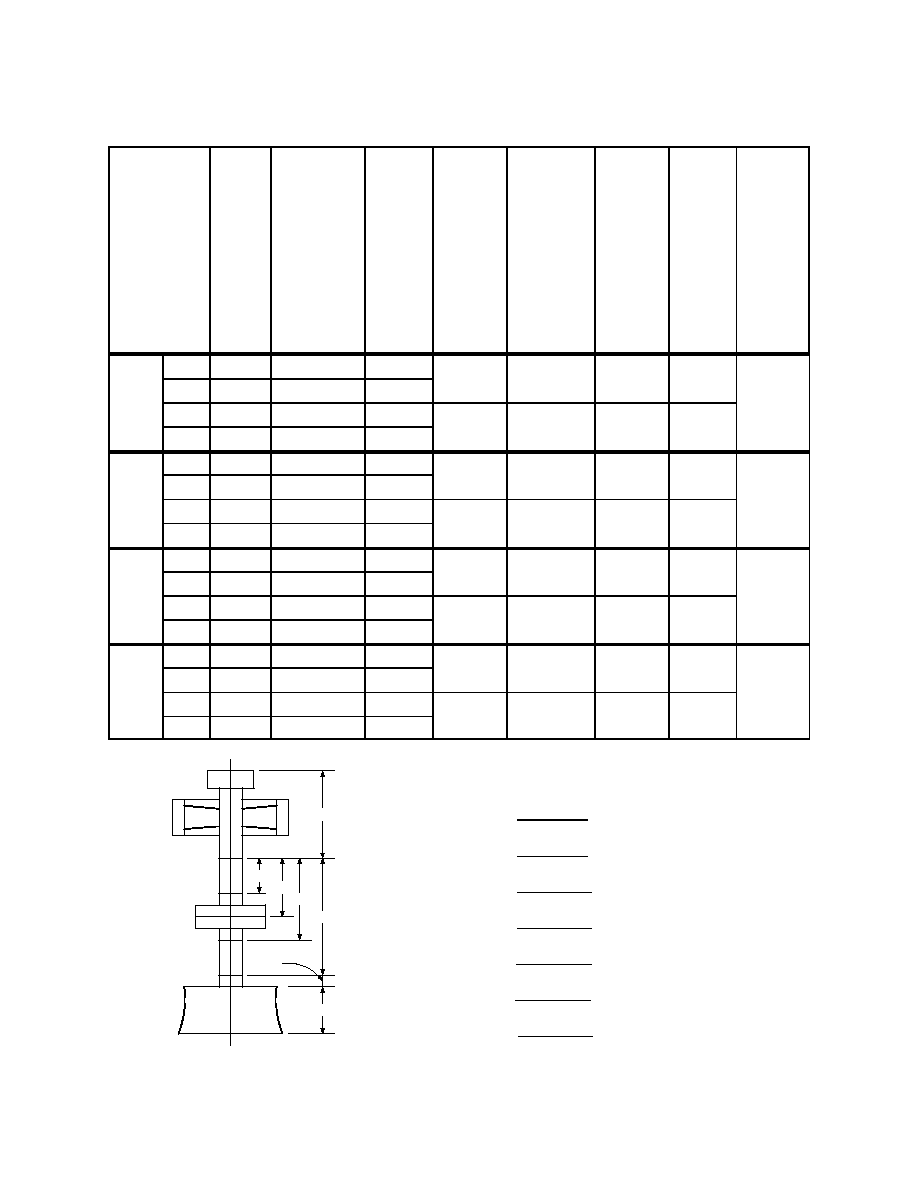

Unit Alignment Worksheet

Column

1

Actual

Reading

Column

2

Mathematical

amount to be

added to

Column 1 to

theoretically

move all wires

an equi-

distance from

center of shaft

Column 3

Total

Column 1

plus

Column 2

Column

4

Difference

N&S

E&W

Column

5

½ Column 4

(Out of Plumb

between top

and bottom

reading)

Column

6

Direction

bottom of

shaft is out

of plumb.

(Direction

of smaller

number in

Column 3)

Column

7

Total

N+S

and

and

E+W

from

Column 3

Column

8

Out of

Roundness

or

inaccuracy

of readings

(N+S)-

(E+W)

(E+W)

Should be

less than

0.002

Fi

rs

t

R

eadi

ng

E

l

evati

evati

o

n

North

0.3445

0.0000

0.3445

0.0000

South

0.1505

0.1940

0.3445

East

0.1710

0.1735

0.3445

0.0000

West

0.2985

0.0460

0.3445

S

e

cond

R

eadi

ng

E

l

evati

evati

o

n

North

0.3425

0.0000

0.3425

0.0035

0.00175

N

0.6885

0.0000

South

0.1520

0.1940

0.3460

East

0.1710

0.1735

0.3445

0.0005

0.00025

W

0.6885

West

0.2980

0.0460

0.3440

Thi

r

d

d

R

eadi

ng

E

l

evati

evati

o

n

North

0.3495

0.0000

0.3495

0.0080

0.0040

N

0.7070

0.0010

South

0.1635

0.1940

0.3575

East

0.1800

0.1735

0.3535

0.0010

0.0005

W

0.7060

West

0.3065

0.0460

0.3525

Fourth

R

eadi

ng

E

l

evati

evati

o

n

North

0.347

0.0000

0.3470

0.0120

0.0060

N

0.706

0.0005

South

0.1650

0.1940

0.3590

East

0.1805

0.1735

0.3540

0.0015

0.00075

W

0.7065

West

0.3065

0.0460

0.3525

A = 170

B = 25

C = 40

D = 55

E = 80

F = 85

G = 25

Figure 14.--Unit alignment worksheet.