14

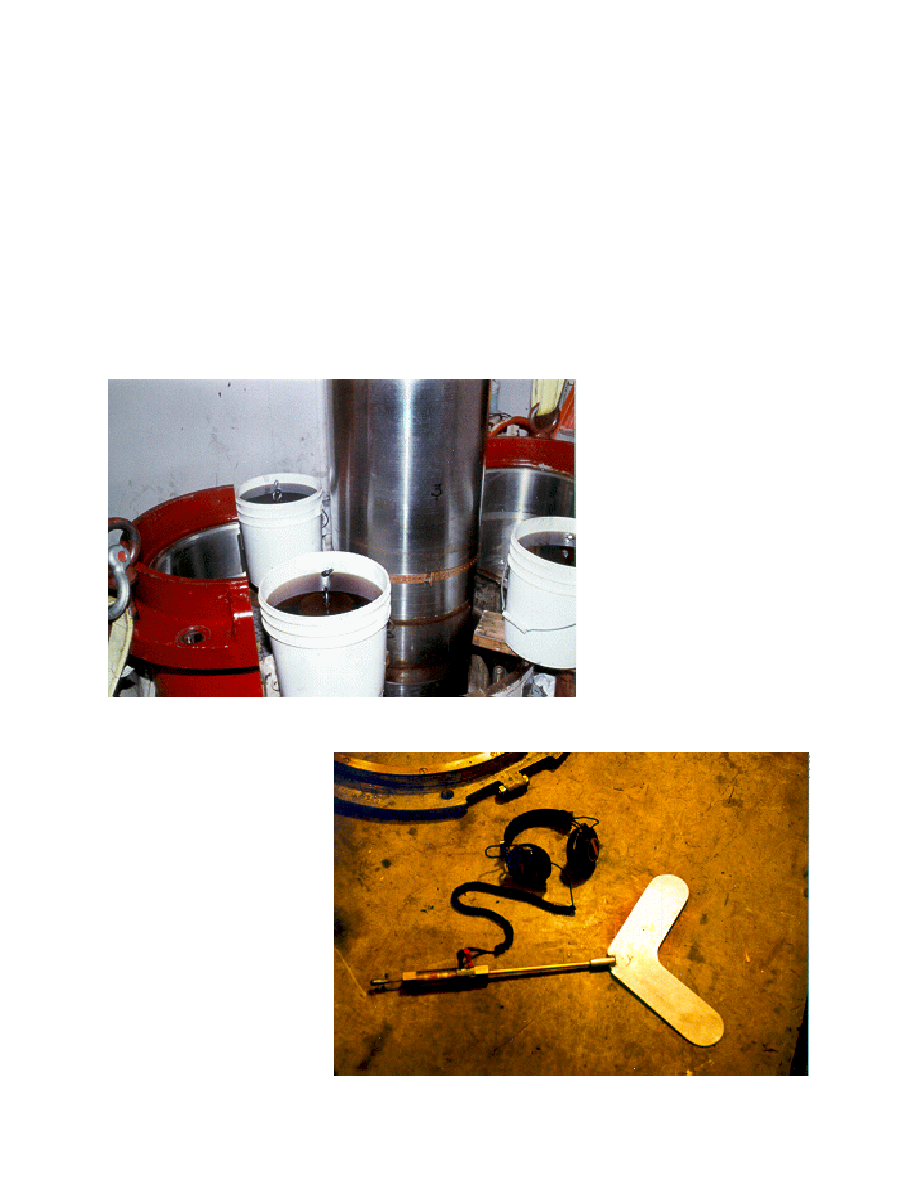

Photograph 2.--Plumb wire setup.

Photograph 3.--Electric micrometer.

4.1 Plumb Wires

The most common method of obtaining plumb readings is with stainless steel, nonmagnetic

piano wires and an electric micrometer. Four wires are hung 90-degrees apart with a finned

plumb bob (photo 2) attached to each wire and suspended in buckets filled with oil to dampen

movement. The electric micrometer (photo 3) is used to measure the distance from the wires to

the shaft. There are variations in design, but the basic concept is the same. The electric

micrometer is made up of an inside micrometer head, head phones, battery, shaft, and "Y-

shaped" end. A simple circuit is completed when the micrometer head touches the plumb wire,

which causes static in the headphones. Banding material is installed on the shaft to provide a

place to rest the "Y" end of the micrometer and to ensure repeatability in the readings.

piano wires and an electric micrometer. Four wires are hung 90-degrees apart with a finned

plumb bob (photo 2) attached to each wire and suspended in buckets filled with oil to dampen

movement. The electric micrometer (photo 3) is used to measure the distance from the wires to

the shaft. There are variations in design, but the basic concept is the same. The electric

micrometer is made up of an inside micrometer head, head phones, battery, shaft, and "Y-

shaped" end. A simple circuit is completed when the micrometer head touches the plumb wire,

which causes static in the headphones. Banding material is installed on the shaft to provide a

place to rest the "Y" end of the micrometer and to ensure repeatability in the readings.

The readings taken with the

electric micrometer are not

calibrated as would be

done with a normal inside

micrometer. Since the wire

is perfectly plumb, the

plumb of the shaft is

determined by comparing

the difference in readings at

different elevations. If the

turbine and generator shafts

were exactly the same

diameter and neither shaft

had any taper, only two

wires, 90 degrees apart

electric micrometer are not

calibrated as would be

done with a normal inside

micrometer. Since the wire

is perfectly plumb, the

plumb of the shaft is

determined by comparing

the difference in readings at

different elevations. If the

turbine and generator shafts

were exactly the same

diameter and neither shaft

had any taper, only two

wires, 90 degrees apart

would be required to obtain

plumb data. Since the

turbine and generator

shaft are rarely exactly the

same diameter and slight

tapers in the shaft are

common, four plumb

wires are normally used,

90 degrees apart. The

difference in the north-

south and the east-west

readings are used in

determining the shaft

plumb. The four wires

turbine and generator

shaft are rarely exactly the

same diameter and slight

tapers in the shaft are

common, four plumb

wires are normally used,

90 degrees apart. The

difference in the north-

south and the east-west

readings are used in

determining the shaft

plumb. The four wires