the center conductor and the

ungrounded tap or flange would be

measured. In the case of bushings

equipped with capacitance taps, a

supplementary test should always be

made on the insulation between the

tap and the flange.

ungrounded tap or flange would be

measured. In the case of bushings

equipped with capacitance taps, a

supplementary test should always be

made on the insulation between the

tap and the flange.

d. The hot-collar test.- This test mea-

sures the condition of a specific small

section of bushing insulation between

an area of the upper porcelain

rainshed and the current-carrying or

center conductor. It is performed by

energizing one or more electrodes

(collars) placed around the bushing

porcelain with the bushing center

conductor grounded. This test is used

to supplement the three tests

described above or to test bushings in

apparatus when the above-mentioned

three tests are either inapplicable or

impractical. Hot-collar tests are

effective in locating cracks in

p o r c e l a i n , d e t e r i o r a t i o n o r

contamination of insulation in the

upper section of a bushing, low com-

pound or liquid level, or voids in com-

pound, often before such defects are

noticeable with the tests outlined in

subparagraphs a., b., and c.

sures the condition of a specific small

section of bushing insulation between

an area of the upper porcelain

rainshed and the current-carrying or

center conductor. It is performed by

energizing one or more electrodes

(collars) placed around the bushing

porcelain with the bushing center

conductor grounded. This test is used

to supplement the three tests

described above or to test bushings in

apparatus when the above-mentioned

three tests are either inapplicable or

impractical. Hot-collar tests are

effective in locating cracks in

p o r c e l a i n , d e t e r i o r a t i o n o r

contamination of insulation in the

upper section of a bushing, low com-

pound or liquid level, or voids in com-

pound, often before such defects are

noticeable with the tests outlined in

subparagraphs a., b., and c.

When bushings with capacitance or potential

taps (92 kV and above) are tested by the

ungrounded test specimen method, it is

recommended practice to include a separate

power-factor test on the tap Insulation as well.

The exception to this is General Electric

Company type of bushings built prior to 1932,

which have tap outlets designed to operate at

less than 100 volts. On all other capacitance

or potential taps, tests are performed at some

voltage from 2 to 5 kV. The procedure is to

energize the tap with the bushing center

conductor and flange grounded. The power

factor of a capacitance or potential tap will

generally be of the order of 1.0 percent or

less.

taps (92 kV and above) are tested by the

ungrounded test specimen method, it is

recommended practice to include a separate

power-factor test on the tap Insulation as well.

The exception to this is General Electric

Company type of bushings built prior to 1932,

which have tap outlets designed to operate at

less than 100 volts. On all other capacitance

or potential taps, tests are performed at some

voltage from 2 to 5 kV. The procedure is to

energize the tap with the bushing center

conductor and flange grounded. The power

factor of a capacitance or potential tap will

generally be of the order of 1.0 percent or

less.

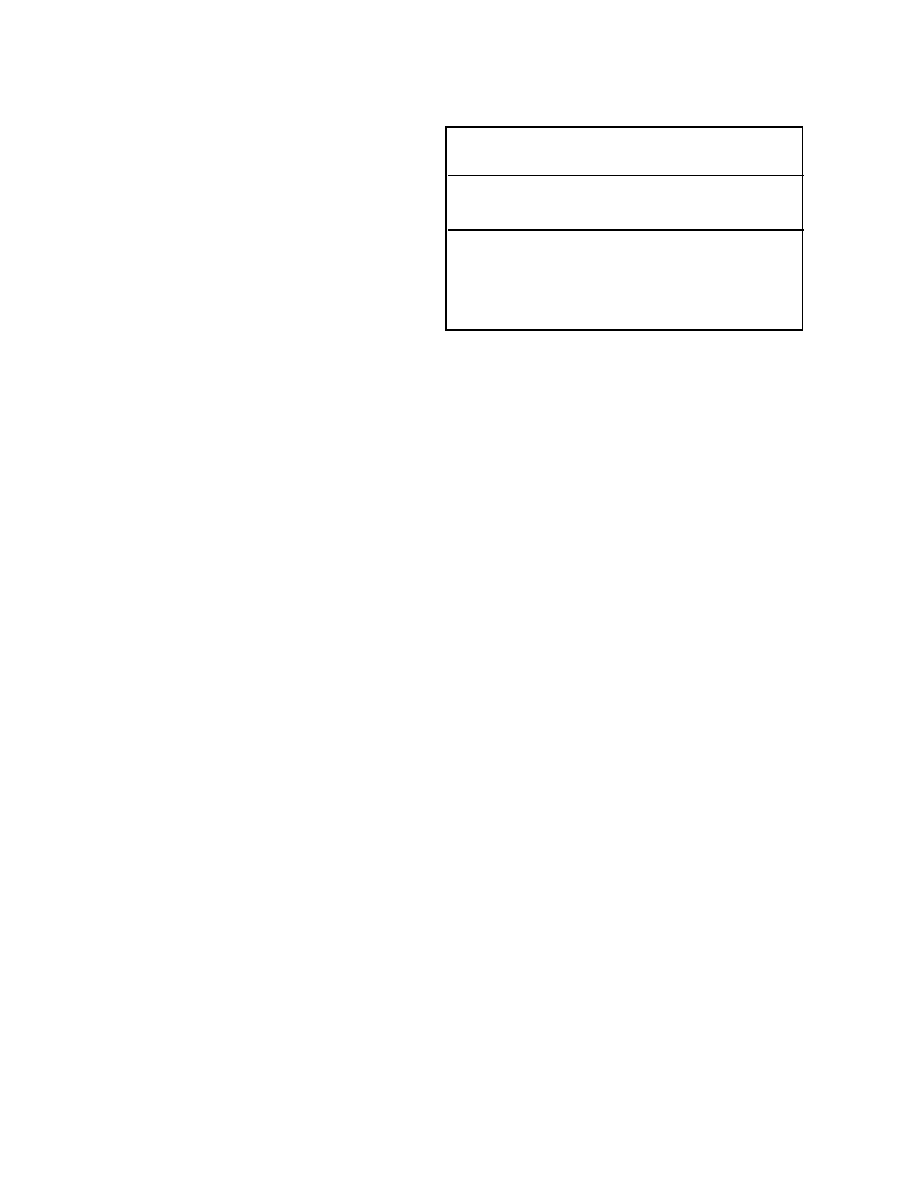

PermissibleTest Potentials to be Applied to

Power-Factor Taps

Manufacturer

Bushing type

Test

or class

volts

General Electric

LC, U

2000

Lapp

POC

2000

Ohio Brass

L

250

Ohio Brass

GK, LK

500

Pennsylvania (Federal Pacific)

P

500

Westinghouse

S, OS

500

Routine tap-insulation tests are not normally

recommended for bushings rated 69 kV and

below with power-factor taps. However, a power-

factor test of the tap insulation should be

performed when questionable ungrounded

specimen test results or visual examination cast

suspicion on the condition of the power-factor

tap. The test procedure is as outlined above for

capacitance taps. In such cases, the maximum

permissible test potentials should be limited to

the following table.

recommended for bushings rated 69 kV and

below with power-factor taps. However, a power-

factor test of the tap insulation should be

performed when questionable ungrounded

specimen test results or visual examination cast

suspicion on the condition of the power-factor

tap. The test procedure is as outlined above for

capacitance taps. In such cases, the maximum

permissible test potentials should be limited to

the following table.

The power factor of the power-factor tap

insulation for most of the above- mentioned

bushings will generally be of the order of 1.0

percent or less. The principal exception to this is

the Ohio Brass, type L bushing. The inherent

properties of the fibrous-bakelite material used

for the tap insulator have resulted in power

factors up to 10 percent for apparently

satisfactory taps.

insulation for most of the above- mentioned

bushings will generally be of the order of 1.0

percent or less. The principal exception to this is

the Ohio Brass, type L bushing. The inherent

properties of the fibrous-bakelite material used

for the tap insulator have resulted in power

factors up to 10 percent for apparently

satisfactory taps.

The tabulations of factory power factors and

power-factors limits in

power-factors limits in

by the manufacturers or otherwise listed by

them. Please note, however, that many bushings

have the factory power factor listed on the

nameplate. In such cases, field measurement,

particularly ungrounded specimen tests, should

compare with and the bushings be rated on the

basis of nameplate power factors. In general, any

bushing that exhibits a history of continued

them. Please note, however, that many bushings

have the factory power factor listed on the

nameplate. In such cases, field measurement,

particularly ungrounded specimen tests, should

compare with and the bushings be rated on the

basis of nameplate power factors. In general, any

bushing that exhibits a history of continued

5 (FIST 3-2 11/91)