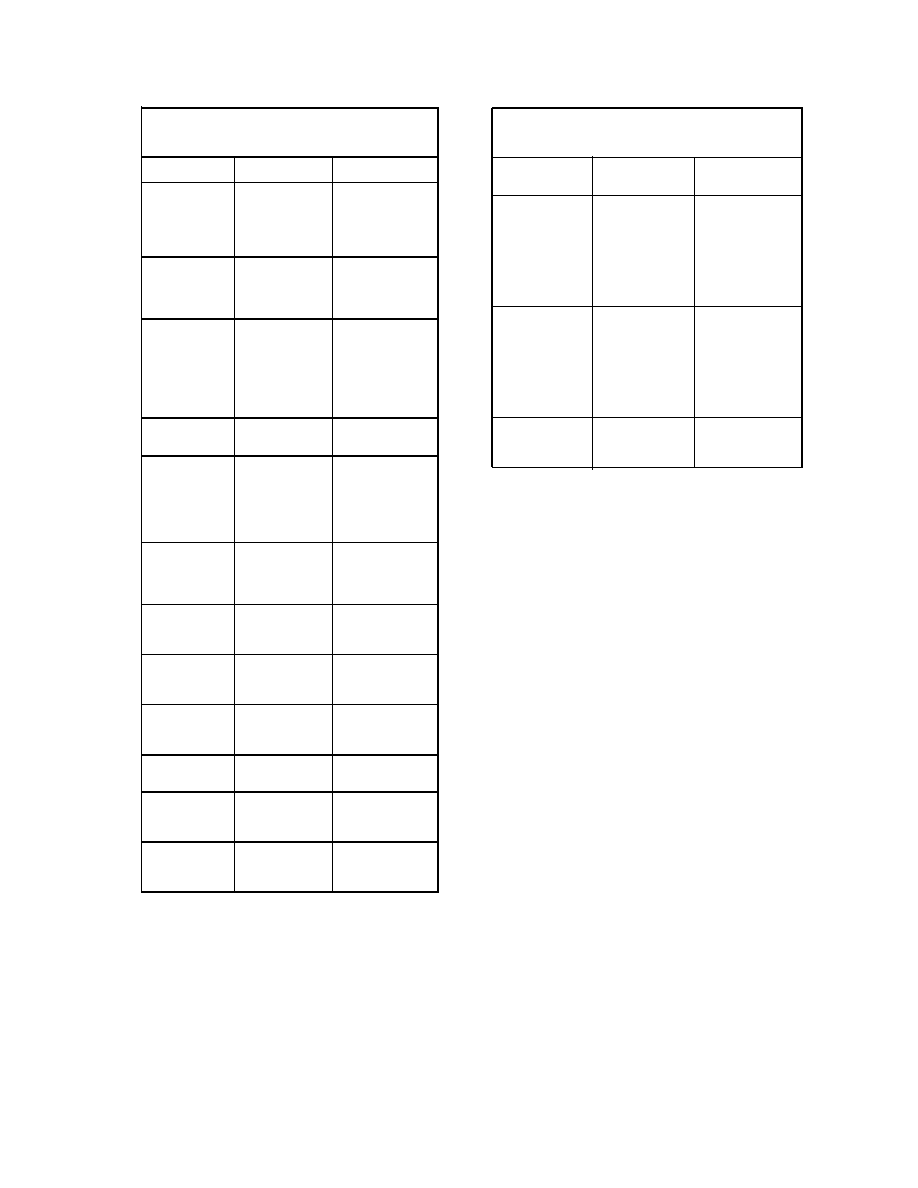

Table 1. - Bushing troubles

Trouble Possible Methods of

results detection

results detection

Cracked porcelain

Moisture enters.

Visual inspection.

Oil and/or gas

Power factor test.

leaks.

Hot collar test

Filler leaks out.

Deterioration of

Moisture enters,

Visual inspection.

cemented joints

Oil and/or gas

Power factor test.

leaks.

Hot collar test.

Filler leaks out.

Gasket leaks

Moisture enters.

Visual inspection.

Oil and/or gas

Power factor test.

leaks.

Hot collar test.

Filler leaks out.

Hot-wire test for

moisture.

Insulation resis-

tance.

moisture.

Insulation resis-

tance.

Moisture in

Moisture enters.

Power factor test,

insulation

Hot collar test.

Solder seal leak

Moisture enters.

Visual inspection.

Filler leaks out.

Power factor test.

Hot collar test.

Hot-wire test for

moisture.

Leak detector.

Hot collar test.

Hot-wire test for

moisture.

Leak detector.

Broken connection

Sparking in appa-

Power factor test.

between ground

ratus tank or

sleeve and flange

within bushing.

Discolored oil.

Discolored oil.

Voids in compound Internal corona.

Hot collar test.

Power factor tip-

up test.

Power factor tip-

up test.

Oil migration

Filler contamina-

Visual inspection.

tion.

Power factor test.

Hot collar test.

Hot collar test.

No oil

Oil leaks out.

Visual inspection,

Moisture enters.

Power factor test.

Hot collar test.

Hot collar test.

Displaced grading

Internal sparking

Hot collar test.

shield

discolors oil.

Electrical fiashover Cracked or bro-

Visual inspection.

ken porcelain.

Hot collar test.

Complete failure.

Lightning

Cracked or bro-

Visual inspection.

ken porcelain.

Test lightning

Complete failure.

arrestors.

(FIST 3-2 11/91) 2

Table 1. - Bushing troubles - Continued

Trouble

Possible

Methods of

results

detection

Corona

Internal break-

Power factor test

down.

Hot collar test.

Radio interfer-

Hot-wire test.

ence.

RRIV

Treeing along sur-

face of paper or

internal sur-

faces.

face of paper or

internal sur-

faces.

Short-circuited

Increased capaci-

Power factor test.

condenser sections

tance.

Voltage test at

Reduced voltage

capacitance tap.

at capacitance

Capacitance test.

tap terminal.

Adds internal

stress to insula-

tion.

Adds internal

stress to insula-

tion.

Darkened oil

Radio interfer-

Power factor test.

ence,

Hot collar test.

Poor test results.

following are minimum suggestions for safety

and are not intended to supersede safety prac-

tices established by individual regions or the

ROMSS.

and are not intended to supersede safety prac-

tices established by individual regions or the

ROMSS.

A. Handling. - When handling bushings,

care must be taken to be sure that rigging is

applied properly to prevent damage to the

bushing and/or to adjacent equipment and

personnel.

care must be taken to be sure that rigging is

applied properly to prevent damage to the

bushing and/or to adjacent equipment and

personnel.

Cracked or chipped porcelain produce sharp

edges which can result in severe cuts on the

hands and arms of personnel working around

them.

edges which can result in severe cuts on the

hands and arms of personnel working around

them.

B. Static Charges. - Static charges induced

by test potentials provide a source for serious

accidents through falls caused by reflex action,

High- static voltages may be encountered at

the bushings installed in apparatus during cold

weather and oil-handling operations. Protective

or safety grounds should be used to bleed off

static charges. High-static charges may also be

encountered at the bushing capacitance

by test potentials provide a source for serious

accidents through falls caused by reflex action,

High- static voltages may be encountered at

the bushings installed in apparatus during cold

weather and oil-handling operations. Protective

or safety grounds should be used to bleed off

static charges. High-static charges may also be

encountered at the bushing capacitance

taps if