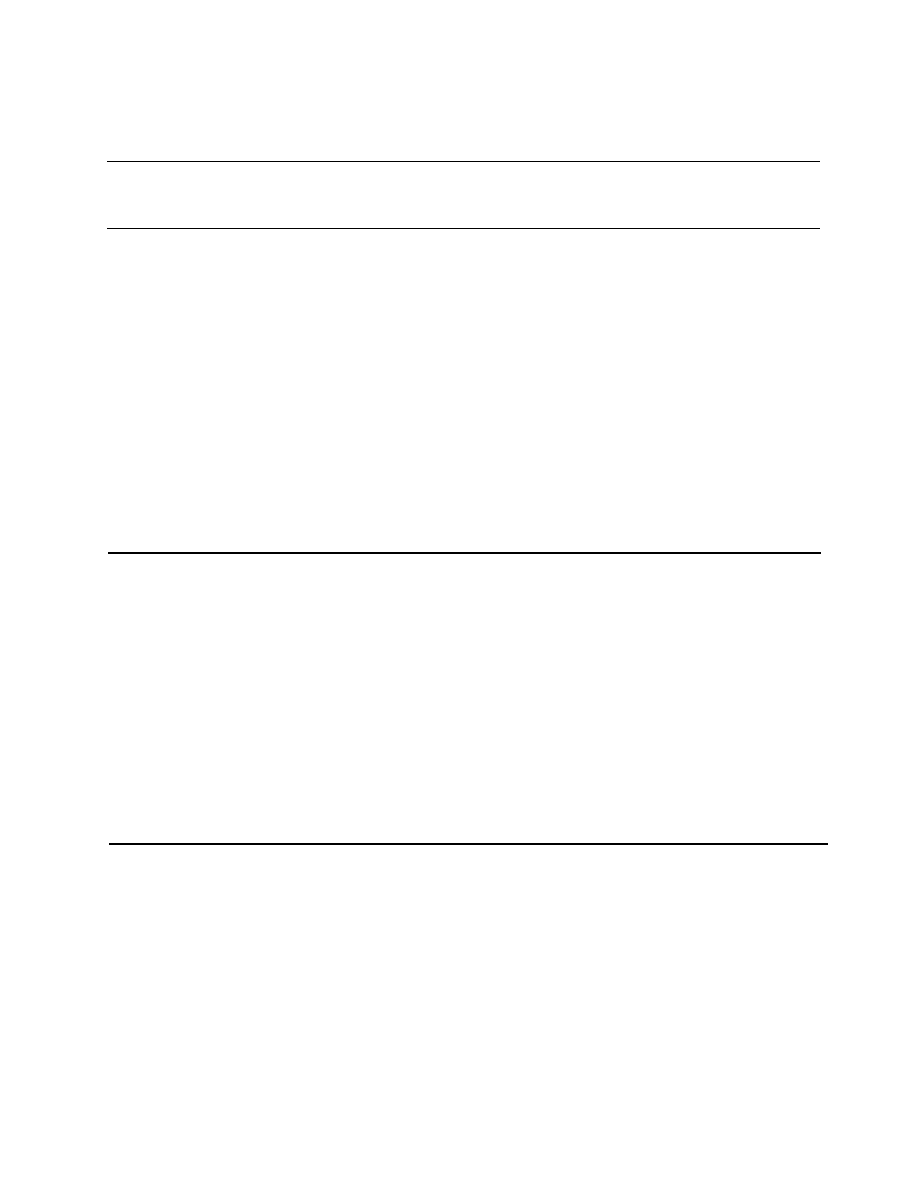

Table 2. - Limiting observable temperature rise of indirectly cooled and directly water-cooled salient pole

synchronous generators and synchronous generator/motors for hydraulic turbine applications - directly

cooled machines manufactured after 1982

cooled machines manufactured after 1982

Method of Water-cooled windings

Item

Machine part

temperature Class B insulation

determination temperatures (°C)

determination temperatures (°C)

(1) Temperature of cold coolant Detector or thermometer.

45 - 50

(Note 1) (Note 2)

(2) Temperature rise of directly cooled Coolant

55 -50

armature windings (Note 3) (Note 2)

(3) Temperature rise of directly cooled Resistance.

55 - 50

field windings. (Note 2)

(4) Temperature rise of cores and Detector or thermometer. 85 -80

mechanical parts in contact

mechanical parts in contact

(Notes 4

with or adjacent to insulation

and 5)

(5) Temperature rise of collector rings. Thermometer.

85

(6) Temperature of miscellaneous parts such as amortisseur windings, rotor surface, brush holders,

brushes, etc., may attain such levels as will not injure the machine in any respect.

brushes, etc., may attain such levels as will not injure the machine in any respect.

Note 1. - The method of coolant temperature measurement shell be optional with the manufacturer

unless otherwise agreed upon. Only one method of temperature measurement shall be required in any

particular case.

Note 2. - Cold coolant temperatures shall be provided within the range of 45 to 50 °C, at the

manufacturer's option, so long as compensating adjustments are made in the rise of the respective parts

so that the sum of the cold coolant temperature and respective part rise does not exceed 100 °C for water

coolant.

Note 3. - Temperature rise of coolant at the outlet of the hottest coil shall be considered the observable

temperature rise of the directly cooled armature winding.

Note 4. - Temperature of the core and mechanical parts in contact with or adjacent to insulating mate-

rial including that of the winding and of core laminations shall not exceed the values in the table.

Temperature of other metal parts, including structural members and shielding devices in the end region, is

not required to be within the limiting temperature, provided that these parts do not appreciably influence

the temperature of insulating material either by contact or radiation. These parts may be operated at

temperatures which are considered safe for the particular metals used.

Note 5. - The values shown for item 4 are limiting regardless of the operating power factor.

unless otherwise agreed upon. Only one method of temperature measurement shall be required in any

particular case.

Note 2. - Cold coolant temperatures shall be provided within the range of 45 to 50 °C, at the

manufacturer's option, so long as compensating adjustments are made in the rise of the respective parts

so that the sum of the cold coolant temperature and respective part rise does not exceed 100 °C for water

coolant.

Note 3. - Temperature rise of coolant at the outlet of the hottest coil shall be considered the observable

temperature rise of the directly cooled armature winding.

Note 4. - Temperature of the core and mechanical parts in contact with or adjacent to insulating mate-

rial including that of the winding and of core laminations shall not exceed the values in the table.

Temperature of other metal parts, including structural members and shielding devices in the end region, is

not required to be within the limiting temperature, provided that these parts do not appreciably influence

the temperature of insulating material either by contact or radiation. These parts may be operated at

temperatures which are considered safe for the particular metals used.

Note 5. - The values shown for item 4 are limiting regardless of the operating power factor.

9. SHORT-TIME AND EMERGENCY

OVERLOADS

During short-time emergencies, loads of 115

percent of the normal loading limit are permissible

at the discretion of the plant superintendent.

OVERLOADS

During short-time emergencies, loads of 115

percent of the normal loading limit are permissible

at the discretion of the plant superintendent.

In extreme emergencies where lack of generation

might cause a system breakup, it may be

necessary to overload machines briefly in excess

of 115 percent of the loading limit and/or

might cause a system breakup, it may be

necessary to overload machines briefly in excess

of 115 percent of the loading limit and/or

7 (FIST 1-4 3/91)