33

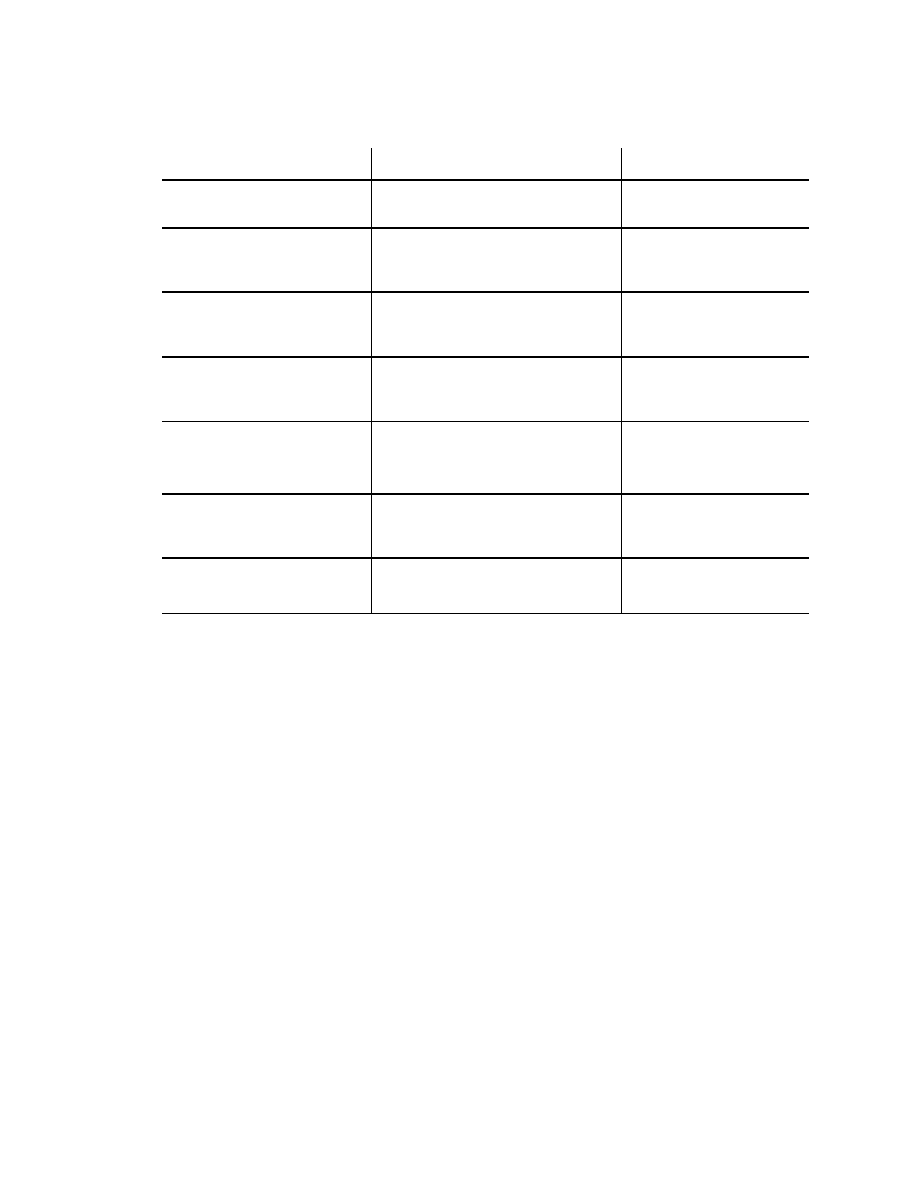

Maintenance or Test

Recommended Interval

Reference

Fault/load study and

recalculate settings

recalculate settings

5 years

Reclamation

Recommended Practice

Recommended Practice

Electro-mechanical relays

Calibration and functional

testing

Calibration and functional

testing

Upon commissioning and every

2 years

2 years

Reclamation

Recommended Practice

Recommended Practice

Solid-state relays

Calibration and functional

testing

Calibration and functional

testing

Upon commissioning

1 year after commissioning

5 years

1 year after commissioning

5 years

Reclamation

Recommended Practice

Recommended Practice

Micro-processor relays

Calibration and functional

testing

Calibration and functional

testing

Upon commissioning

1 year after commissioning

8-10 years

1 year after commissioning

8-10 years

Reclamation

Recommended Practice

Recommended Practice

Protection circuit functional

test

test

Annually

FIST Volume 3-8

Manufacturer's

Instruction Books

Manufacturer's

Instruction Books

Check red light lit for lockout

relay and circuit breaker coil

continuity

relay and circuit breaker coil

continuity

Daily

1

Reclamation

Recommended Practice

Recommended Practice

Lockout relays

Cleaning and lubrication

Cleaning and lubrication

5 years

Power Equipment Bulletin

No. 6

No. 6

1

In staffed plants, in conjunction with daily operator control board checks. Otherwise, check each

visit to the plant.

Supervisory Control and Data Acquisition (SCADA) systems are computer-based, real-

time control systems for power and water operations. Since these systems are in

operation continuously and are in many ways self-diagnosing, regular maintenance

and testing is not necessary except as recommended by the manufacturer. However,

circuits that are infrequently used may require periodic functional testing to ensure

they will be operational when the need arises.

time control systems for power and water operations. Since these systems are in

operation continuously and are in many ways self-diagnosing, regular maintenance

and testing is not necessary except as recommended by the manufacturer. However,

circuits that are infrequently used may require periodic functional testing to ensure

they will be operational when the need arises.

Security requirements affecting SCADA are dictated by documents such as

Presidential Decision Directive 63: Critical Infrastructure Protection, May 22, 1998

and Office of Management and Budget (OMB) Circular A-130, Appendix III, Security

of Federal Automated Resources, February 8, 1996. Periodic audits, Critical

Infrastructure Protection Plans (CIPP), and regularly scheduled security training are

important requirements of SCADA security.

Presidential Decision Directive 63: Critical Infrastructure Protection, May 22, 1998

and Office of Management and Budget (OMB) Circular A-130, Appendix III, Security

of Federal Automated Resources, February 8, 1996. Periodic audits, Critical

Infrastructure Protection Plans (CIPP), and regularly scheduled security training are

important requirements of SCADA security.