26

·

Power O&M Bulletin No. 19 -

Maintenance Schedules and Records

·

IEEE Std. 432-1992, Guide for Insulation Maintenance for Rotating Electric

Machinery (5 hp to 10,000 hp).

Machinery (5 hp to 10,000 hp).

·

IEEE Std. 95-1997, Recommended Practice for Insulation Testing of Large

AC Rotating Machinery with High Direct Voltage

AC Rotating Machinery with High Direct Voltage

·

Conditions Rating Procedures/Condition Indicator for Hydropower Equipment,

U.S. Army Corps of Engineers

U.S. Army Corps of Engineers

·

Handbook to Assess the Insulation Condition of Large Rotating Machines,

Volume 16, Electric Power Research Institute (EPRI)

Volume 16, Electric Power Research Institute (EPRI)

·

Electric Generators, Power Plant Electrical Reference Series, Volume 1, EPRI

·

Inspection of Large Synchronous Machines, I. Kerszenbaum

·

Test Procedure for Synchronous Machines, IEEE 115-1983

·

Guide for Operation and Maintenance of Hydrogenerators, IEEE Std. 492-1974

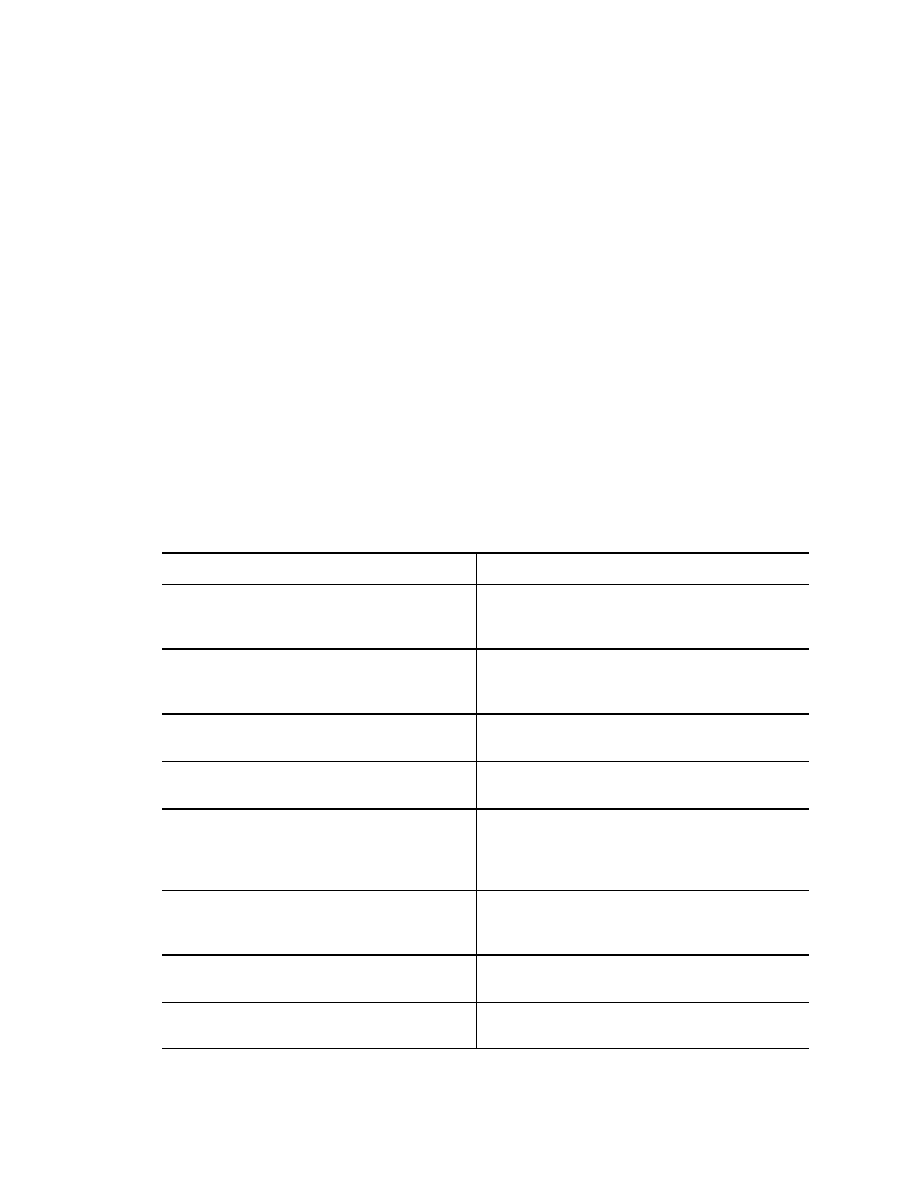

Maintenance or Test

Recommended Interval

Preventive maintenance and inspections

No standard recommended interval. Machine

specific PM according to site operating

conditions. Also, see Appendix B.

specific PM according to site operating

conditions. Also, see Appendix B.

Stator winding - physical inspection

During 1-, 2½-, and 5-year warranty inspections;

thereafter, during major maintenance outages

but not to exceed 5 years.

thereafter, during major maintenance outages

but not to exceed 5 years.

Stator winding - high voltage DC ramp test

3 to 5 years and after prolonged maintenance

outage.

outage.

Stator winding - insulation resistance

polarization index (

polarization index (

megohmmeter)

Performed in lieu of HVDC ramp test

Stator winding - AC high potential test

At factory and as an acceptance test. Non-

routine thereafter but may be used to verify

insulation integrity before and/or after stator

winding repair.

routine thereafter but may be used to verify

insulation integrity before and/or after stator

winding repair.

Stator winding - partial discharge

measurements (corona probe/scope)

measurements (corona probe/scope)

Benchmarked within first 5 years of operation

then annually thereafter. Three- to six-month

intervals if deterioration detected.

then annually thereafter. Three- to six-month

intervals if deterioration detected.

Stator winding - black out test

Nonroutine. Performed when deterioration is

suspected.

suspected.

Stator winding - ozone measurement

Nonroutine. Performed when deterioration

detected.

detected.