in order to "work" the sample in the container.

One cyclic movement of the plunger up and

down is known as a "double stroke." The grease

worker is fitted with a thermometer to provide a

check on the sample temperature.

One cyclic movement of the plunger up and

down is known as a "double stroke." The grease

worker is fitted with a thermometer to provide a

check on the sample temperature.

Additional apparatus includes a water bath for

bringing the grease to the proper temperature,

and a standard cutter for use in cutting samples

of block grease.

bringing the grease to the proper temperature,

and a standard cutter for use in cutting samples

of block grease.

Procedure: The initial procedure depends on

the type of penetration to be determined. Un-

disturbed penetration requires only the opening

of the grease container; unworked penetration

requires transfer of the sample to the test cup.

Worked and prolonged worked penetrations

involve first the transfer of the sample to the

cup, followed by the working procedure. Block

penetration requires the cutting of a sample with

the grease cutter. Sample size should be about

1 pound for most penetration determinations.

For block penetration, a 2-inch cube is the re-

quired sample. Samples are brought to 77° F in

either the water bath or an air bath (for block

penetration) before penetration is measured.

the type of penetration to be determined. Un-

disturbed penetration requires only the opening

of the grease container; unworked penetration

requires transfer of the sample to the test cup.

Worked and prolonged worked penetrations

involve first the transfer of the sample to the

cup, followed by the working procedure. Block

penetration requires the cutting of a sample with

the grease cutter. Sample size should be about

1 pound for most penetration determinations.

For block penetration, a 2-inch cube is the re-

quired sample. Samples are brought to 77° F in

either the water bath or an air bath (for block

penetration) before penetration is measured.

Following this initial procedure, the sample is

placed on the penetrometer platform. The cone

is placed in the zero position with its tip just

touching the surface of the sample. The cone is

released and allowed to drop for 5 seconds. The

penetration is read on the indicator in tenths of

a millimeter (A penetration of 200 means that

the cone moved 20.0 millimeters into the

grease). This procedure is performed three

times for each determination; the average of the

3 readings is recorded as the penetration.

placed on the penetrometer platform. The cone

is placed in the zero position with its tip just

touching the surface of the sample. The cone is

released and allowed to drop for 5 seconds. The

penetration is read on the indicator in tenths of

a millimeter (A penetration of 200 means that

the cone moved 20.0 millimeters into the

grease). This procedure is performed three

times for each determination; the average of the

3 readings is recorded as the penetration.

When only a small amount of grease can be

obtained, an alternate cone penetration method

is available. ASTM D 1403, "Cone Penetration

of Lubricating Grease Using One-Quarter and

One-Half Scale Cone Equipment," may be used

for samples as small as 5 grams.

obtained, an alternate cone penetration method

is available. ASTM D 1403, "Cone Penetration

of Lubricating Grease Using One-Quarter and

One-Half Scale Cone Equipment," may be used

for samples as small as 5 grams.

Significance: If a grease is too soft, it may not

stay in place, resulting In poor lubrication. If a

grease Is too hard, it will not flow properly, and

either fail to provide proper lubrication or cause

difficulties in dispensing equipment. These

statements sum up the reasons for classifying

greases by consistency. Penetration numbers

are useful for classifying greases according to

the consistencies required for various types of

service, and in controlling the consistency of a

given grade of grease from batch to batch.

stay in place, resulting In poor lubrication. If a

grease Is too hard, it will not flow properly, and

either fail to provide proper lubrication or cause

difficulties in dispensing equipment. These

statements sum up the reasons for classifying

greases by consistency. Penetration numbers

are useful for classifying greases according to

the consistencies required for various types of

service, and in controlling the consistency of a

given grade of grease from batch to batch.

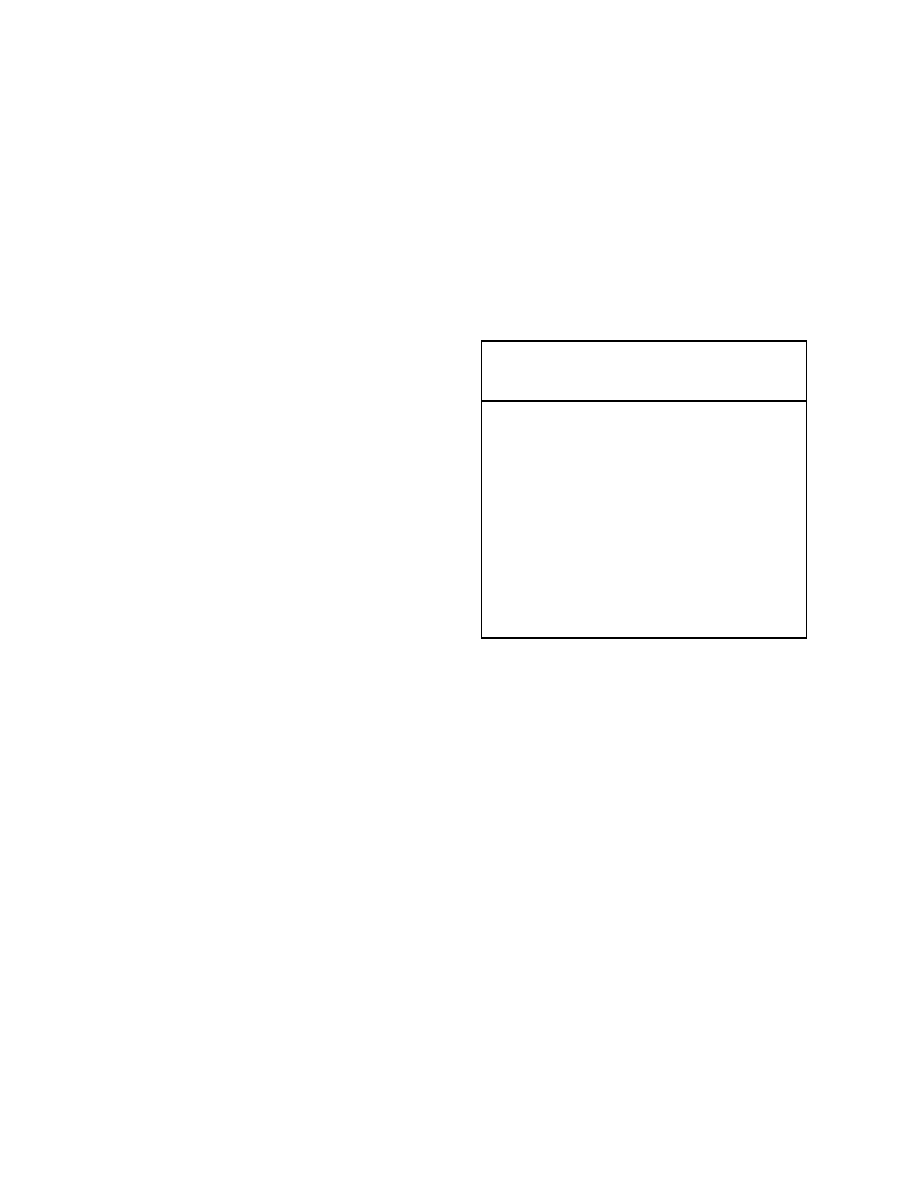

NLGL Grade

Worked Penetration

Range mm/10

000 ................................................ 445-475

00 .................................................. 400-430

0 .................................................... 355-385

1 .................................................... 310-340

2 .................................................... 265-295

3 .................................................... 220-250

4 .................................................... 175-205

5 .................................................... 130-160

6 ...................................................... 85-115

00 .................................................. 400-430

0 .................................................... 355-385

1 .................................................... 310-340

2 .................................................... 265-295

3 .................................................... 220-250

4 .................................................... 175-205

5 .................................................... 130-160

6 ...................................................... 85-115

The National Lubricating Grease Institute has

classified greases according to their worked

penetrations. These NLGI grades, shown in the

accompanying table, are used for selection of

greases in various applications.

classified greases according to their worked

penetrations. These NLGI grades, shown in the

accompanying table, are used for selection of

greases in various applications.

In comparing greases, worked and prolonged

worked penetrations are generally the most

useful values. The change in penetration be-

tween the 60-stroke value and prolonged worked

value is a measure of grease stability.

Prolonged worked penetrations should report the

amount of working (10,000 and 100,000 strokes

are most common) in order to be useful.

worked penetrations are generally the most

useful values. The change in penetration be-

tween the 60-stroke value and prolonged worked

value is a measure of grease stability.

Prolonged worked penetrations should report the

amount of working (10,000 and 100,000 strokes

are most common) in order to be useful.

A-9 (FIST 2-4 11/90)